The Buzz on 24??media

The Buzz on 24??media

Blog Article

The Only Guide for 24??media

Table of ContentsSome Known Questions About 24??media.10 Simple Techniques For 24??media24??media - QuestionsGetting My 24??media To WorkGet This Report about 24??media

Developments in print modern technology are altering the interactions playing area when it pertains to top quality, affordability and sophisticated capabilities. Countered printing and electronic printing are the major processes whereby print work are embarked on both making use of four-color printing approaches. Each choice has its benefits, supplying various techniques to meet the demands of diverse manufacturing jobs.

Commonly, this has been the most constant strategy for specifically preserving color suits, making it perfect for print runs that only require fixed printing such as pre-printed forms, brochures, leaflets, calling card, and bulk postcard mailings. Nevertheless, as a result of the fixed nature of litho printing, it is not optimal for variable print pieces that will be sent by mail to individual receivers such as statements, letters, and personalized postcards.

The smart Trick of 24??media That Nobody is Discussing

The most recent advancements in print innovation are helping to bring a lot of balanced out's benefits into the digital printing world genuinely altering the face of modern printing! There are some essential differences between Offset Printing and Digital Printing (Digital Printing). This guide reveals the benefits and downsides of each printing approach. There is an obvious and expanding number of advantages to utilizing the electronic print process.

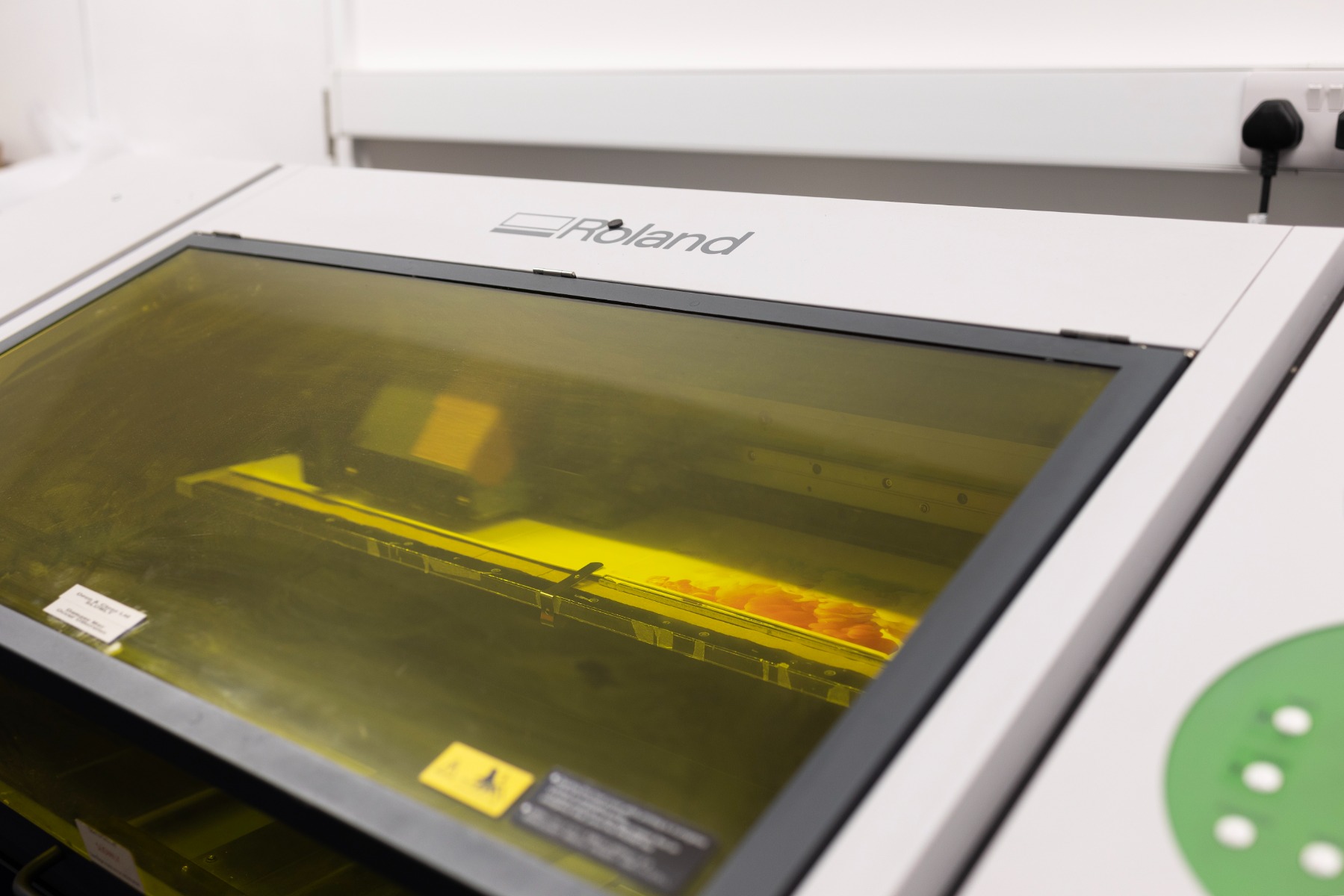

Today's digital print devices is amongst the most advanced on the market. Here are several of the largest benefits of utilizing electronic printing: control the digital print space, with full-color printing finished in one process and effortlessly printed straight from a print file. Without an extensive set-up process, the calibration time of a particular job is reduced, adding to quicker print time and total shipment.

The inkjet printing procedure has aided to change the market along with the high quality and speed of the result. The most current inkjet technology can print on traditional countered stocks with plain, silk, and glossy coatings. Top notch digital print coupled with software-managed shade administration practices adds optimum value to print items and makes manufacturing processes a lot more reputable than balanced out.

24??media Can Be Fun For Everyone

(https://filesharingtalk.com/members/610008-za24media?tab=aboutme&simple=1)

Eco-friendly and eco-friendly inks and printer toners are likewise readily available for even more sustainable printing. Digital print additionally eliminates the need to clean plates or blankets with unsafe chemicals at the end of the printing process.

Variable data helps organizations reach their specific consumers and audience with uniquely-created and customized content. As innovation improves, the top quality of electronic printing has become second-to-none, with greater detail, color suit abilities and overall precision. Without the requirement to clean plates or utilize excess ink, digital printing is likewise much less wasteful and usually more ecologically pleasant.

Conventional printing approaches, such as countered lithography ("offset") and flexography ("flexo"), entail numerous make-ready actions to move an initial image to a substrate. These approaches call for the production of a collection of plates installed on a cyndrical tube to move ink that develops the preferred picture when incorporated on paperboard and various other packaging products. Small Volume Packaging.

Our 24??media PDFs

Digital printing, with fewer relocating pieces, is more agile than balanced out in this regard.

It's a means to blend your packaging and marketing strategies. Reduced set-up time conserves money on the front end. And given that these are not substantial mass orders, smaller sized companies can manage to print more tips here without having to fulfill the higher and extra expensive print limits of conventional printing. Digital printing aids safeguard your brand against counterfeiting by integrating obvious and covert solutions on your product packaging.

Make sure you work together with a printing and packaging partner who has the best qualifications. While eleventh-hour printing and customization are a substantial benefit, electronic may not constantly be the very best technique for you. Balance out printing has the benefit of cost-effectiveness with huge print runs, specifically those with innovative decorative impacts and specialized layers.

Indicators on 24??media You Need To Know

The positive plate, with its smooth surface, brings in oil-based inks and repels water. In contrast, the unfavorable plate, with its harsh texture, takes in water and pushes back oil. Rubber rollers are after that utilized to move the picture from the plate to the corrugated surface area.

Corrugated paper can sometimes verify to be a difficult surface to print on, but Litho prints to a different surface area and is after that laminated to it, making it simple to print top notch photos. It can be incredibly constant, even for futures. Actually, the extra you publish, the less costly the prices come to be for Litho.

What Litho does not offer you is precisely what Digital does, customization. Pricey established up Longer turn-around No Variable Data Printing Smaller sized color gamut, shades can be less intense Digital printing is the process of printing electronic photos directly onto the corrugated substrate using a single-pass, direct-to-corrugate method.

Report this page